It takes many to make a single shawl

Harvesting the Pashmina, Laddakh

Preparing Double Yarn lengths for Loom

Specialist Shawl Washerman

A hand-made Kashmir kani shawl cannot be made by one person alone. It is an act of cooperation and faith between several specialists. Unlike a plain, checks or striped pashmina shawl where a shuttle is used, a patterned kani takes the effort and expertise of several women, men and youngsters and a long time to complete.

The story begins with the hard work of the pashmina goat and sheep herders of Ladakh who shear and sell the wool. Kashmiri women, sort, grade clean and spin the wool. Men and boys double it and twist it into yarn. Specialist dyers dye the wool yarn in specified natural or chemical colours. The best paid are the designers or Naqqash that design the shawl. Pattern drawers draw it on a graph paper and colour it. The design is then converted by a Talim-Guru into a shorthand or Talim understood by the weavers.

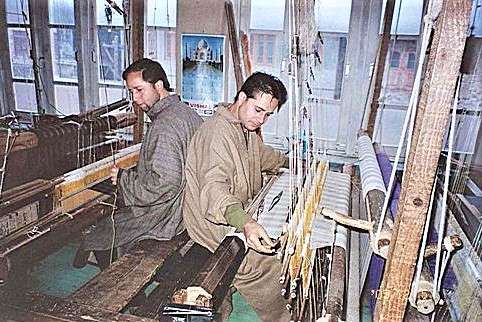

The warp-maker assembles the warp on the loom. The warp-dresser sizes the warp with stiff glue starch. The warp-threaders, nowadays women, thread the warp through the heddles. Every shawl needs 2-3000 double threaded warps. Then the weavers, who have filled hundreds of spools/tujis with coloured thread, sit down at the loom and start weaving.

The completed shawl laden with dirt and starch is washed in snow-fed gushing river waters by specialist washermen or dhobi. Any shawl damage is repaired by the rafugar and threads trimmed by the purzgar. Finally, it is professionally ironed by a presswala. Then enter the shawl sellers or traders who are family members or shopkeepers who find the suitable customers to sustain the livelihoods of the various craftsmen (karigars).

Spinning Pashmina on a Charkha

Weaving Pashmina shawls on handloom

Specialist Pashmina Dyer